Tekheniki Parameter

Ka tlase ke liparamente tsa walnut shell strainer

Li-parameter tsa tikoloho ea mosebetsi:

Khatello ea ho sebetsa: ≤0.6MPa; Khatello ea metsi a kenang: ≥0.4MPa;

Khatello ea metsi e kenang ka morao: ≥ 0.15MPa; Phapang ea khatello ea ho kena le ho tsoa: 0.1-0.2MPa

Mokhoa oa ho sebetsa oa parameter:

Mofuta oa khatello; Mokhoa oa ts'ebetso: ho phalla ha metsi ho tloha holimo ho ea tlaase; Lebelo la ho sefa: 20-25m / h; Potoloho ea ts'ebetso: 8-24h;

Mokhoa oa ho hlatsoa mokokotlo: ho hlatsoa metsi;

Tšebeliso ea metsi ka morao: 1-3%; Matla a ho hlatsoa mokokotlo: 4-15l / s·m2;

Nako ea ho hlatsoa ka morao: 20-30min; Sekhahla sa ho atolosa mokokotlo: 30-50%

Phello ea kalafo:

Metsi a hloekisang a mahoashe: oli, ≤100mg / L, SS, ≤50mg / L;

Mokelikeli: oli, ≤10mg / L, SS, ≤10mg / L;

Metsi a hloekileng a hloekileng: oli, ≤20mg / L, SS, ≤20mg / L;

Mokelikeli: oli, ≤5mg / L, SS, ≤5mg / L;

Mehato e 'meli ea ho kenngoa ha metsi: oli, ≤100mg / L, SS, ≤50mg / L;

Mokelikeli: oli, ≤5mg / L, SS, ≤5mg / L;

Matla a ho thibela 6-20kg/m3

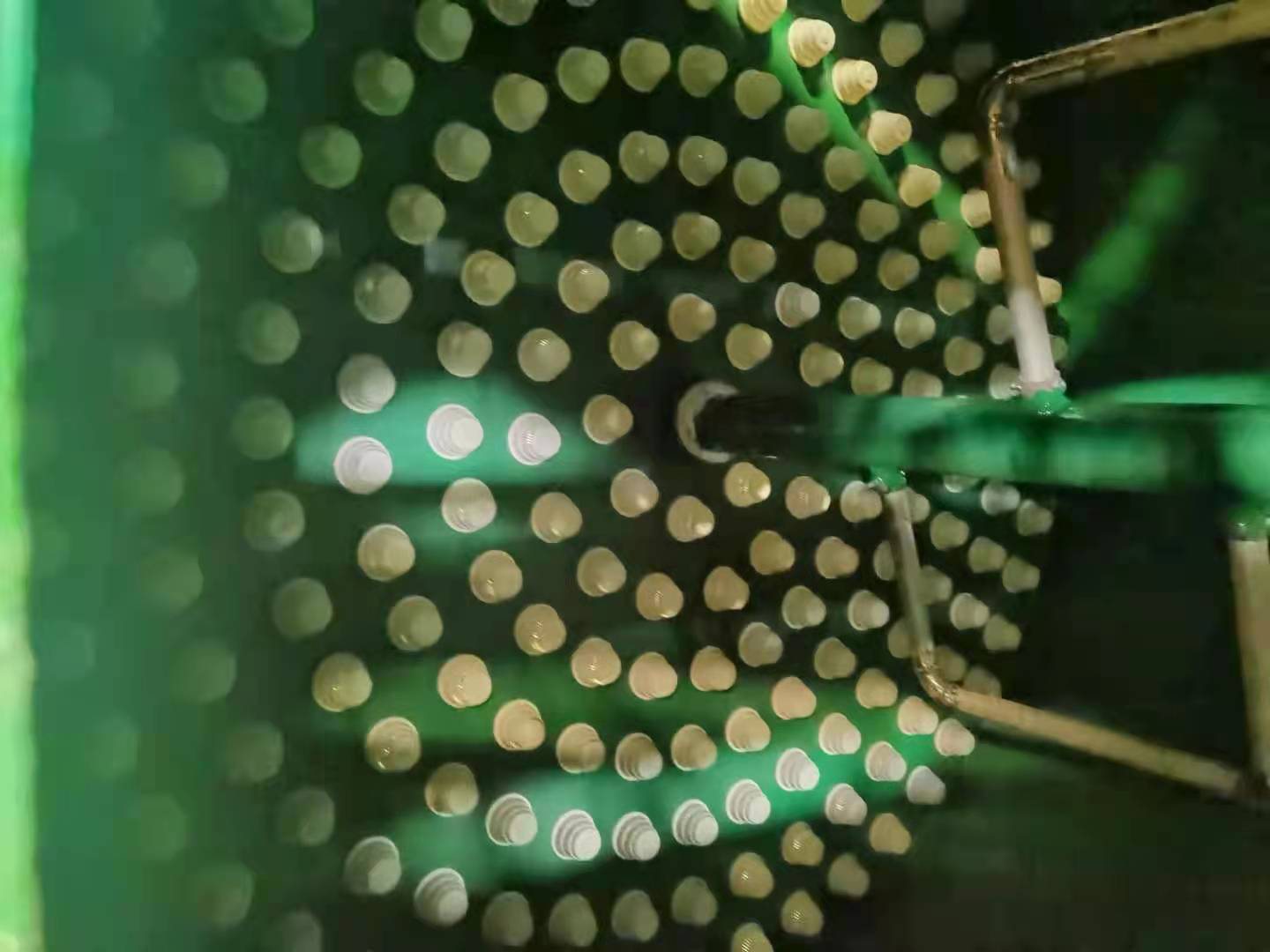

Molemo oa sehlahisoa oa Walnut Shell Filter

1. Ka lebaka la tlhaho ea hydrophilic eseng oli-philic, khetla ea walnut e hlohlelletsoa ho senya e mong le e mong ka har'a mokhatlo ha ho hlajoa ka morao, e le hore bokhoni ba ho senya bo be matla, bokhoni ba ho tsosolosa bo matla, botsitso ba lik'hemik'hale bo botle, bo loketseng nako e telele ea botsitso ba ts'ebetso ea filthara.

2. Thepa ea walnut shell fiter e nka ho hloekisa bethe e tebileng, e ka ntlafatsang haholo matla a ho thibela.

3. Tšebeliso ea maze e thibelang ho thibela metsi ho e-na le skrine e tloaelehileng ea kabo ea metsi, ho qoba sefahla nakong ea ts'ebetso ka keketseho ea nako kapa liphetoho tsa boleng ba metsi le ts'ebetso ea thibelo.

4. Matla a adsorption le palo e kholo ea tšilafalo e thibelang;

5. Ho hanyetsa ho qoelisoa ha oli, ho tlosoa ha oli ka makhetlo a mabeli le taba e emisitsoeng;

6. Ho tsosolosoa habonolo, ho hlatsoa mokokotlo ntle le meriana;

7. E ka kopanngoa ka letoto kapa ka ho bapisa.

Lisebelisoa

1. Phekolo ea likhoerekhoere tse nang le oli tse tsoang masimong a oli le Marine, masimo a petrochemical le metallurgical.

2. Phekolo ea likhoerekhoere tse nang le oli koung, likoung le litsing tsa oli.

3. Phekolo ea likepe le likhoerekhoere tse ling tse mafura.

4. E sebetsa ts'ebetsong ea ts'ebetso ea ho tsosolosa le ea ho hloekisa ea likhoerekhoere tse nang le oli le mekhoa e meng ea ho tsosolosa metsi a litšila ka tšepe le tšepe, indasteri ea metallurgical, indasteri ea mashala.

5. E loketse ho hloekisoa hantle ha metsi a reinjection a masimo a oli a nang le metsi a mangata, metsi a hlahisoang ho tloha sethaleng sa oli sa offshore le metsi a tsosolositsoeng ho tsoa ho boiler ea ho tsosolosa e chesang ea tšimo ea oli e boima.

6. E loketse bakeng sa phekolo ea filtration le phekolo e tsoetseng pele ea ho pholile ho potoloha metsi ka mochine oa matla, ho hloekisa le semela sa petrochemical.