molao-motheo oa ho sebetsa

Ha filthara ea laminated e sebetsa ka mokhoa o tloaelehileng, metsi a phalla ka har'a sefe ea laminated, a sebelisa lebota le groove ho bokella le ho thibela litšila.Karolo e ka hare-hare ea groove e fana ka ho sefa ka mahlakore a mararo ho tšoana le ho hlahisoang ka lehlabathe le lehlohlojane.Ka hona, katleho ea eona ea ho sefa e phahame haholo.Ha filthara ea laminated e sebetsa hantle, filthara ea laminated e notletsoe.Setlhopha se boetse sea sutheha kapa se hlatsuoa ka bohona.Ha ho hlatsuoa ka letsoho ho hlokahala, tlosa ntho e sefang, lokolla nate ea compression, 'me ue hlatsoe ka metsi.Ka nako e ts'oanang, e matla ho feta ho boloka litšila tsa letlooa, kahoo palo ea ho hlatsoa e batla e le tlase, ho sebelisoa ha metsi ho fokotseha.Leha ho le joalo, letlapa la laminated le tlameha ho lokoloha ka boeona ha le hlatsoa ka mokhoa o itekanetseng.Ka lebaka la tšusumetso ea lintho tse phelang le litšila tsa lik'hemik'hale 'meleng oa metsi, maqephe a mang a laminated a atisa ho khomarela 'me ha ho bonolo ho hlatsoa ka ho feletseng.

Mokhoa oa ho sebetsa

Ha filthara ea laminated e sebetsa ka mokhoa o tloaelehileng, metsi a phalla ka har'a sefe ea laminated, a sebelisa lebota le groove ho bokella le ho thibela litšila.Karolo e ka hare-hare ea groove e fana ka ho sefa ka mahlakore a mararo ho tšoana le ho hlahisoang ka lehlabathe le lehlohlojane.Ka hona, katleho ea eona ea ho sefa e phahame haholo.Ha filthara ea laminated e sebetsa hantle, filthara ea laminated e notletsoe.Setlhopha se boetse sea sutheha kapa se hlatsuoa ka bohona.Ha ho hlatsuoa ka letsoho ho hlokahala, tlosa ntho e sefang, lokolla nate ea compression, 'me ue hlatsoe ka metsi.Ka nako e ts'oanang, e matla ho feta ho boloka litšila tsa letlooa, kahoo palo ea ho hlatsoa e batla e le tlase, ho sebelisoa ha metsi ho fokotseha.Leha ho le joalo, letlapa la laminated le tlameha ho lokoloha ka boeona ha le hlatsoa ka mokhoa o itekanetseng.Ka lebaka la tšusumetso ea lintho tse phelang le litšila tsa lik'hemik'hale 'meleng oa metsi, maqephe a mang a laminated a atisa ho khomarela 'me ha ho bonolo ho hlatsoa ka ho feletseng.

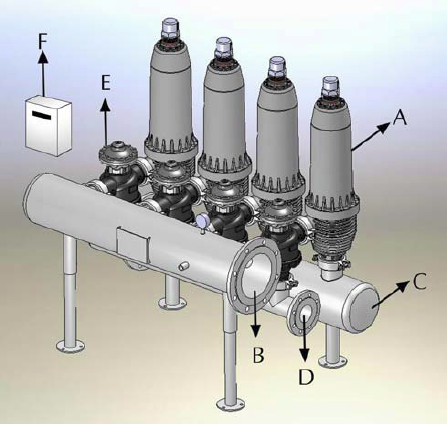

Tlhophiso

Metsi a phalla ka har'a sesefa ka har'a filthara, "filter stack" e hatelloa ka thata hammoho ke "filter stack" tlas'a ts'ebetso ea matla a selemo le matla a hydraulic, likaroloana tse sa hloekang li kenngoa sebakeng sa ho tšela, metsi a hloekisitsoeng a phalla ka ntle ho mocha o moholo oa sefa, ka nako ena valve ea tsela e le 'ngoe ea diaphragm e bulehile.

Hlatsoa mokokotlo

Ha phapang e itseng ea khatello e fihletsoe, kapa nako e behiloeng, tsamaiso e kena ka ho toba sebakeng sa backwash, molaoli o laola valve ho fetola tsela ea ho phalla ha metsi, diaphragm ea tsela e le 'ngoe e ka tlaase ho filthara e koala mocha o moholo, backwash e kena ka lihlopha tse 'ne tsa kanale ea nozzle,' me kanale ea molomo e hokahaneng le phaposi ea piston ea khatello ea metsi ea phahama, piston e ea holimo ho hlola khatello ea selemo holim'a qubu, ebe e lokolla sebaka sa piston ka holim'a qubu.Ka nako e ts'oanang, metsi a ho hlatsoa ka morao a fafatsoa ka lebelo le phahameng ho tloha ho 35 * 4 li-nozzles ka holim'a lihlopha tse 'nè tsa likanale tsa li-nozzle ho latela tsela ea tangent ea stack, e le hore stack e potolohe le ho arohana ka tsela e lekanang.Metsi a ho hlatsoa a fafatsoa ho hlatsoa bokaholimo ba qubu, 'me litšila tse kenngoeng holim'a qubu li fafatsoa ebe li lahleloa ka ntle.Ha backwash e phethiloe, tataiso ea phallo e fetoha hape, laminate e hatelloa hape, 'me tsamaiso e boetse e kena sebakeng sa filtration.

Tekheniki Parameter

| Lisebelisoa tsa likhetla | peipi ea tšepe e entsoeng ka polasetiki |

| Sefa hlooho matlo | nylon e matlafalitsoeng |

| Lintho tse entsoeng ka laminated | PE |

| Sefa sebaka (laminated) | 0.204 limithara tse lisekoere |

| Ho nepahala ha tlhoekiso (um) | 5, 20, 50, 80, 100, 120, 150, 200 |

| Litekanyo (bolelele le bophara) | 320mmX790mm |

| Khatello ea ho sebetsa | 0.2MPa -- 1.0MPa |

| Khatello ea mokokotlo | ≥0.15MPa |

| Sekhahla sa ho phalla ha mokokotlo | 8-18m /h |

| Nako ea ho hlatsoa mokokotlo | 7 -- 20S |

| Tšebeliso ea metsi ka morao | 0.5% |

| Mocheso oa metsi | ≤60 ℃ |

| Boima ba 'mele | 9.8kg |

Melemo ea lihlahisoa

1.Filtration e nepahetseng: Lipoleiti tsa filthara tse nang le lintlha tse fapaneng li ka khethoa ho ea ka litlhoko tsa metsi, ho kenyelletsa le 20 micron, 55 micron, 100 micron, 130 micron, 200 micron, 400 micron le litlhaloso tse ling, 'me tekanyo ea ho hloekisa e kholo ho feta 85%.

2. Ho hlatsoa ka mokhoa o phethahetseng le o sebetsang hantle: Hobane li-pores tsa filthara li buloa ka ho feletseng nakong ea ho hlatsoa mokokotlo, hammoho le ente ea centrifugal, phello ea ho hloekisa e ke ke ea finyelloa ke lihlopha tse ling.Ts'ebetso ea ho hlatsoa mokokotlo e nka feela metsotsoana e 10 ho isa ho e 20 ka yuniti ea sefe.

3.Opereishene e feletseng ea othomathike, ho tsoa ha metsi ho tsoelang pele: nako le khatello ea khatello ea ho laola ho qala ha backwash.Sistimi ea filthara, yuniti e 'ngoe le e' ngoe ea filthara le li-workstations li hlatsuoa ka tatellano.Ho fetola ka mokhoa o ikemetseng pakeng tsa libaka tse sebetsang le tsa ho hlatsoa morao ho ka etsa bonnete ba hore metsi a ntse a tsoela pele, tahlehelo e tlaase ea khatello ea tsamaiso, 'me phello ea ho hloekisa le ho hlatsoa mokokotlo e ke ke ea senyeha ka lebaka la nako ea tšebeliso.

4.Modular moralo: Basebedisi ba ka khetha palo ea li-filter tse tšoanang ho ea ka tlhokahalo, e feto-fetohang le e fetohang, e matla e fetohang.Tšebeliso e feto-fetohang ea sebaka sa sekhutlo sa sebaka, ho latela maemo a sebaka se tlase sa ho kenya.

5.Tlhokomelo e bonolo: hoo e batlang e se tlhokahalo ea tlhokomelo ea letsatsi le letsatsi, tlhahlobo le lisebelisoa tse khethehileng, likarolo tse seng kae tse senyehang.Sehlahisoa sa laminated ha se hloke ho nkeloa sebaka, 'me bophelo ba ts'ebeletso bo ka ba lilemo tse 10.

Sebaka sa Kopo

1.Fill filter kapa lehlakoreng le ka lehlakoreng la metsi a potolohang a tora e pholileng: e ka rarolla bothata ba ho potoloha ho thibela metsi, ho fokotsa tšebeliso ea matla, le ho fokotsa litekanyetso, ho thibela ho hlōleha le ho koala le ho fokotsa litšenyehelo tsa tlhokomelo ea tsamaiso.

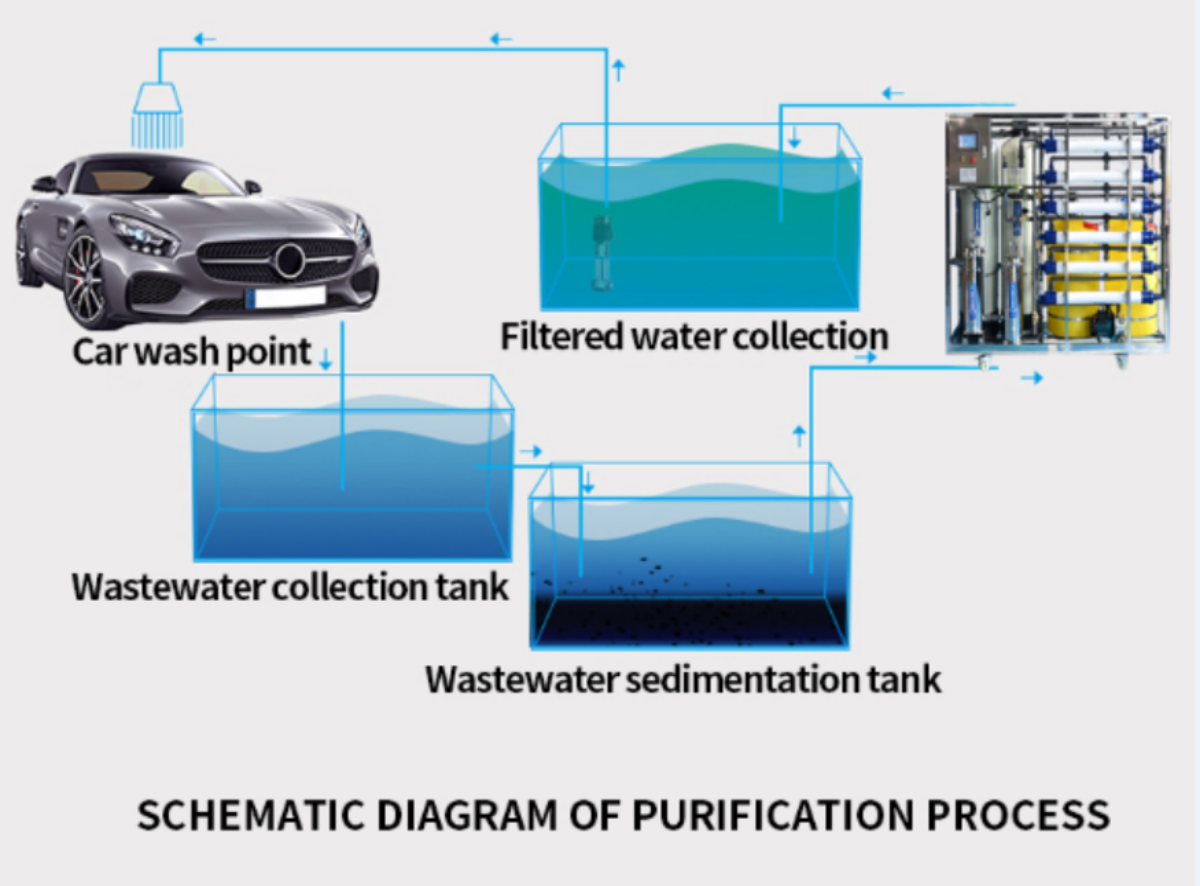

2. Tšebeliso e ncha ea metsi le ts'ebeliso ea likhoerekhoere esale pele: boloka palo eohle ea metsi, ntlafatsa boleng ba metsi a sebelisitsoeng, fokotsa kapa ho qoba tšilafalo e bakoang ke phallo ea likhoerekhoere ka kotloloho tikolohong.

3.Desalination pretreatment: tlosa litšila le likokoana-hloko tsa Marine metsing a leoatle.Ho hanyetsa letsoai le ho hanyetsa ha kutu ea sefe ea polasetiki ho molemo ho feta lisebelisoa tse ling tsa tšepe tse theko e boima haholo.

4.Primary filtration pele ultrafiltration le reverse osmosis membrane kalafo: ho sireletsa precision filter element le ho lelefatsa bophelo ba eona ba tšebeletso.

Ntle le moo, li-filters tsa laminated li sebelisoa haholo ho: indasteri ea lik'hemik'hale, matla a motlakase, tšepe, tlhahiso ea mechini, ts'ebetso ea lijo le lino, polasetiki, pampiri, meepo, metallurgy, textile, petrochemical, tikoloho, lebala la kolofo, koloi, filthara ea metsi a pompo.